Whatever You Required to Understand About the Uses and Advantages of Aluminum Castings

Aluminum castings play a crucial duty throughout numerous markets, using special homes that improve product performance. Their lightweight nature and toughness make them excellent for applications in automotive and aerospace markets. In addition, the flexibility of casting approaches enables intricate styles and limited tolerances. As the need for lasting remedies climbs, recognizing the benefits and applications of aluminum castings becomes significantly crucial. What certain advantages do they supply over various other materials?

Review of Aluminum Casting Processes

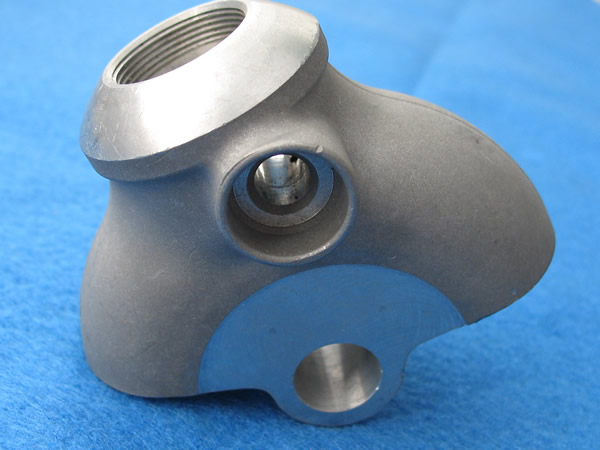

Aluminum casting processes encompass a variety of strategies used to shape liquified aluminum into wanted forms. These approaches consist of sand casting, pass away casting, and financial investment casting, each offering unique advantages depending on the application (Aluminum Casting). Sand spreading involves creating a mold from sand, permitting elaborate layouts and huge elements, while die casting uses high pressure to infuse liquified aluminum into metal mold and mildews, guaranteeing accuracy and smooth coatings. Financial investment spreading, also called lost-wax spreading, generates complex forms with excellent dimensional precision, making it ideal for detailed components

These processes are characterized by their ability to create light-weight, resilient components that display superb deterioration resistance. The adaptability of aluminum permits personalization in various sectors, from vehicle to aerospace. Furthermore, the capacity to recycle aluminum boosts the sustainability of these casting processes, decreasing ecological impact while preserving product honesty. Understanding these strategies is essential for maximizing production effectiveness and accomplishing premium aluminum castings.

Trick Applications of Aluminum Castings

Aluminum castings play a vital function throughout various industries, specifically in automobile, aerospace, and consumer electronic devices. In the automotive field, they contribute to light-weight frameworks that enhance gas performance. Likewise, aerospace elements profit from aluminum's strength-to-weight proportion, while customer electronics take advantage of its convenience for reliable production.

Automotive Market Applications

As the vehicle industry proceeds to develop, producers progressively rely on aluminum castings for their light-weight yet long lasting homes. These castings play a crucial function in boosting car performance, gas performance, and total security. Key applications include engine blocks, transmission real estates, and architectural components, which benefit from aluminum's exceptional strength-to-weight ratio. Additionally, aluminum castings help with intricate geometries, enabling for ingenious designs that improve the rules of aerodynamics and minimize drag. The deterioration resistance of aluminum likewise adds to durability, decreasing maintenance expenses for both producers and consumers. As electric automobiles gain popularity, aluminum castings are vital for battery units and various other parts, better solidifying their relevance in the future of automotive manufacturing.

Aerospace Element Production

In the aerospace sector, aluminum castings are integral to the manufacturing of light-weight, high-performance parts. These castings are important for producing components such as engine real estates, architectural frameworks, and touchdown gear parts, where weight reduction is important for gas efficiency and general efficiency. The outstanding strength-to-weight proportion of aluminum permits the advancement of intricate geometries that enhance the rules of aerodynamics. In addition, aluminum's resistance to rust adds to the longevity and reliability of aerospace components, making certain safety in flight procedures. The spreading procedure additionally enables accurate resistances, which is essential in meeting strict aerospace market criteria. Overall, aluminum castings play an essential duty in advancing aerospace innovation while sustaining the industry's push for sustainable methods.

Customer Electronic Devices Manufacturing

Making use of aluminum castings in consumer electronics production has ended up being significantly significant because of their light-weight and sturdy homes. Suppliers leverage these castings to create elements for different gadgets, including smartphones, laptops, and pc gaming consoles. Aluminum's superb thermal conductivity additionally assists in warm dissipation, improving device performance and longevity. Moreover, the versatility of aluminum permits detailed layouts and complicated geometries, allowing sleek and modern aesthetic appeals that appeal to customers. Additionally, aluminum castings can be conveniently reused, aligning with the growing demand for sustainable manufacturing methods. As technology breakthroughs, the function of aluminum castings in developing ingenious and efficient customer electronics is anticipated to expand, making them a staple in the sector.

Benefits of Utilizing Aluminum Castings

While numerous materials are readily available for casting, aluminum attracts attention because of its unique mix of lightweight properties, stamina, and corrosion resistance. The reduced thickness of aluminum makes it a suitable option for applications where weight reduction is crucial, such as in the automotive and aerospace markets. Its exceptional strength-to-weight proportion allows producers to create resilient components without adding excessive weight.

Additionally, aluminum castings can be generated with detailed styles and limited resistances, making it possible for intricate geometries that are hard to accomplish with various other materials. The versatility of aluminum permits numerous casting techniques, consisting of sand, pass away, and investment spreading, dealing with varied manufacturing needs. Aluminum's convenience of machining and completing improves its allure, promoting the creation of top quality surface finishes. Generally, the benefits of making use of aluminum castings add to boosted efficiency and efficiency in various applications across different industries.

Corrosion Resistance in Aluminum Castings

All-natural Oxide Layer

A natural oxide layer forms on the surface of aluminum castings, supplying a crucial obstacle against ecological variables that can result in deterioration. This slim, protective movie is an outcome of the aluminum's reaction with oxygen airborne, successfully shielding the underlying metal from dampness, chemicals, and contaminants. Therefore, aluminum castings display impressive deterioration resistance, which improves their long life and resilience in numerous applications. The oxide layer is not only advantageous for protection however likewise adds to visual top qualities, as it can establish a matte coating that numerous markets like. In addition, this natural procedure minimizes the requirement for additional layers, making aluminum castings an economical choice for producers looking for reputable, long-lasting materials.

Alloy Variants Influence

The composition of aluminum alloys substantially influences their rust resistance homes in castings. Various alloy variants, such as 1xxx, 2xxx, and 6xxx collection, exhibit unique degrees of sensitivity to corrosion. For instance, 1xxx alloys, largely made up of pure aluminum, offer outstanding rust resistance as a result of their high purity. On the other hand, 2xxx alloys, which contain copper, may experience considerable rust when revealed to harsh environments. Meanwhile, 6xxx alloys, incorporating magnesium and silicon, strike a balance in between stamina and resistance. The visibility of alloying components can boost or lessen safety oxide layers, inevitably affecting longevity and efficiency. Recognizing these variants is crucial for selecting the right alloy for specific applications where corrosion resistance is critical.

Layout Flexibility and Customization

Although various materials exist for casting applications, aluminum attracts attention as a result of its remarkable layout adaptability and capacity for personalization. This convenience enables designers and engineers to develop detailed shapes and kinds that fulfill details practical requirements. Aluminum Casting. The reduced thickness of aluminum allows lightweight designs, which is especially valuable in markets such as automobile and aerospace, where weight reduction is important

Aluminum castings can be customized to different specifications, consisting of wall surface thickness, surface area finish, and dimensional resistances. This adaptability not only boosts the aesthetic allure however additionally enhances the performance of the end product. Additionally, progressed methods such as 3D printing and computer-aided design (CAD) more help with the customization process, enabling fast prototyping and decreasing preparations. Aluminum castings can successfully meet the varied needs of different markets while supplying producers the capacity to innovate and respond swiftly to market needs.

Comparison With Various Other Casting Products

While numerous casting materials each have their distinct benefits, aluminum consistently shows premium homes that make it a recommended selection in many applications. Contrasted to iron and steel, aluminum is substantially lighter, which reduces the general weight of completed items, improving gas performance in automotive and aerospace industries. Additionally, aluminum supplies excellent corrosion resistance, requiring less maintenance in time compared to products like iron, which can corrosion.

When juxtaposed with plastics, aluminum's stamina and durability surpass many synthetic alternatives, making it suitable for demanding environments. Furthermore, aluminum's thermal and electrical conductivity is remarkably greater than many other metals, making it perfect for applications requiring efficient heat dissipation or electrical elements.

Future Trends in Aluminum Casting Innovation

Innovations in aluminum casting modern technology are readied to redefine its Check This Out applications across different sectors. Developments in automation and robotics are streamlining manufacturing processes, improving performance and accuracy. The combination of expert system and artificial intelligence makes it possible for real-time tracking and anticipating upkeep, decreasing downtime and enhancing quality assurance.

Additionally, the advancement of innovative alloys is expanding the performance capacities of aluminum castings, making them ideal for more demanding applications, especially in vehicle and aerospace sectors. Sustainable techniques are additionally acquiring grip, with boosted emphasis on reusing aluminum and lowering carbon impacts during manufacturing.

Additive manufacturing strategies, such as 3D printing, are being discovered to develop intricate geometries that typical techniques can not attain, enabling greater layout versatility. These fads show a future where aluminum casting will not just fulfill but surpass sector assumptions, driving development and sustainability in production.

Often Asked Concerns

Just How Are Aluminum Castings Recycled After Usage?

Aluminum castings are normally collected, cleaned, and refined in reusing centers. The material is melted down, refined, and afterwards changed into brand-new items, thereby preserving resources and reducing environmental impact while maintaining aluminum's preferable residential properties.

What Are the Normal Prices Connected With Aluminum Castings?

The common prices connected with aluminum castings vary based upon aspects such as complexity, volume, and product requirements. Normally, costs range from a couple of dollars per extra pound to considerably greater quantities for elaborate designs and large he has a good point amounts.

Exactly How Do Aluminum Castings Compare in Weight to Steel Castings?

Aluminum castings evaluate considerably less than steel castings, typically around one-third the weight (Aluminum Casting). This lowered mass permits much easier handling, transportation, and application in numerous markets, contributing to boosted effectiveness in design and production processes

What Industries Largely Depend On Aluminum Castings?

Various sectors substantially depend on aluminum castings, including vehicle, aerospace, electronics, and durable goods. Their lightweight nature, deterioration resistance, and adaptability make them important for manufacturing elements in these sectors, improving performance and effectiveness.

Exist Any Type Of Health Dangers Connected With Aluminum Casting Processes?

Health risks linked with aluminum casting processes include direct exposure to fumes, dirt, and chemicals, which can lead to respiratory system problems and skin irritability. Correct precaution and devices are vital to reduce these prospective dangers in the office.